Background inspection of truck tyres Help and Advice

Inspection des pneus sur un camion

The right pressure for truck and bus tyres

Choosing and maintaining the correct inflation pressure is key for optimum performance.

Inflation Pressure

Choosing and maintaining the correct inflation pressure is key for optimum performance.

The tyre is the sole point of contact between the vehicle and the road surface.

It is crucial to the safety both of users and goods transported. For a given load and type of work, in clearly defined conditions, there is only one suitable inflation pressure.

The pressure of the air in the tyre is crucial to its correct operation: it is this pressure which both supports and moves loads or people:

- Safely

- Durably

- Economically

- Comfortably

However, in the surveys conducted by Michelin, pressure emerges as one of the maintenance points which is often not monitored and maintained as well as it should be.

Pressure and safety

Incorrect tyre pressure has a negative impact on certain basic aspects of safety performance such as:

- Casing strength

- Vehicle stability and handling

- Grip

- Sensitivity to kerbing

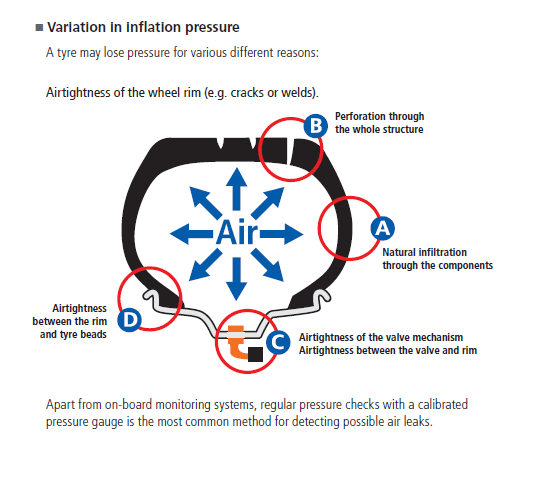

Variation in inflation pressure

A tyre can lose pressure for various reasons:

- Airtightness of the rim (e.g. cracks or welds)

- A hole that goes through the structure

- Natural infiltration through component parts

Apart from on-board monitoring systems, a regular, visual pressure check using a pressure gauge is the most common way of detecting problems with air leaks.

the right pressure

REASONS FOR INFLATION PRESSURE CHECK

■ Pressure checks should be made on all the tyres on the vehicle:

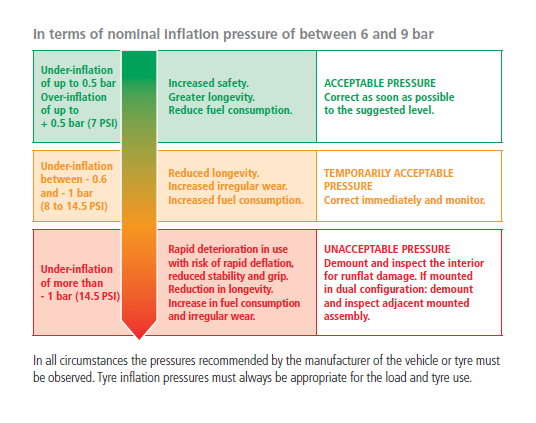

- If the inflation pressure is too low, the result is an abnormal rise in running temperature which may lead to damage to the internal components. This damage is irreversible and may cause the destruction of the tyre and rapid deflation.

- The consequences of running with insufficient pressure in the tyres are not necessarily immediate and may even become apparent after the pressure has been corrected.

- The spare tyre should also be checked.

- Tyre pressures must be checked on cold tyres regularly or when the vehicle is serviced, using a calibrated pressure gauge.

- Insufficient inflation pressure also greatly increases the risk of aquaplaning.

- Over-inflation can cause rapid and irregular wear and increased sensitivity to impact (tread damage, casing failure).

- Even if tyres are inflated with nitrogen, the pressure still needs to be checked regularly.

image 2020 07 08 15 16 01 011

Important precautions

- Tyre pressures must be checked on cold tyres at ambient temperature. The pressure increases in use: never reduce the pressure of a tyre while it is hot.

- Never re-inflate a tyre which has been running underinflated without a thorough inspection both inside and out.

- Under inflation could result in the tyres running at abnormally high temperatures, leading to thermal degradation of the tyres’ components’. The degradation is irreversible and can result in a rapid deflation of the tyre.

- Under-inflation leads to:

- An increase of rolling resistance and thus vehicle’s fuel consumption

- A reduction in tyre service life (mileage)

- An impact on vehicle handling and safety

- A reduction in casing resistance which limits the potential of retreading

- Over-inflation reduces:

- Safety and ride comfort

- Grip

- Tyre service life (mileage), particularly on drive axles tyres

- Tyre pressures greater than 10 Bar (145 PSI) are not recommended for normal highway operations.

- Inflation pressures on cold tyres which are more than 0.6 bar (8 PSI) below the suggested values must be corrected immediately.

- The regulations in force in the country of use are to be observed in all cases.

- Use an accurate, regularly calibrated pressure gauge and handle it with care.

- If the pressure in a tyre checked when hot is lower than the suggested pressure, the tyre must be removed and checked, complying with the safety instructions.

- If one tyre appears considerably hotter than the others, it must also be removed and checked complying with the safety instructions.

- The inflation pressures of the tyres on the same axle should normally be about the same.

- The pressure should be checked 24 hours after a tyre has been fitted.

- Tyres for commercial vehicles should be inflated to a pressure relevant to the load, speed and conditions of use.

- Guidelines on pressures are shown in the load/pressure tables.

- Using the correct pressure is essential to the safe operation of the tyre.

- The valve cap is the primary air seal and must always be fitted

(NB. The valve core acts as a one way valve to allow the tyre to be inflated; it should not be treated as a seal).

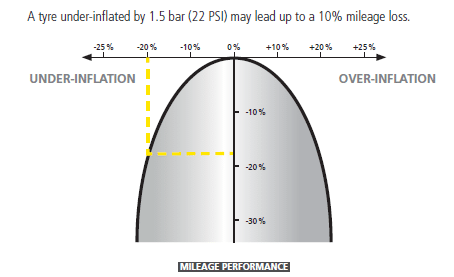

The influence of tyre pressure on mileage performance

Under-inflation by 1.5 bar (21.7 psi) = 10% performance loss

influence

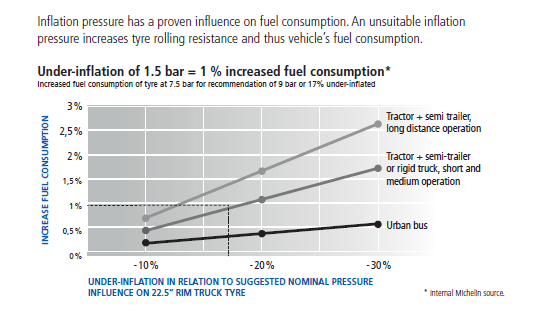

The influence of tyre pressure on fuel consumption

Inflation pressure has a proven influence on fuel consumption. An unsuitable inflation pressure increases the rolling resistance of tyres and therefore the vehicle's fuel consumption.

Under-inflation by 1.5 bar (21.7 psi) = 1% excess consumption

Excess consumption when tyres inflated to 7.5 bar (109 psi) not the recommended 9 bar (130.5 psi), i.e. 17% over-inflation

fuel consumption

Picto the right pressure page 75 Help and Advice

Tips box about tyre pressure check

These help and advice pages might also interest you:

• Tyre marking and basics

• Tyre structure and functions

• Operating advice

• Regulations in the UK

• European legislation

• All you need to know about European truck tyre labelling